OUR SERVICES

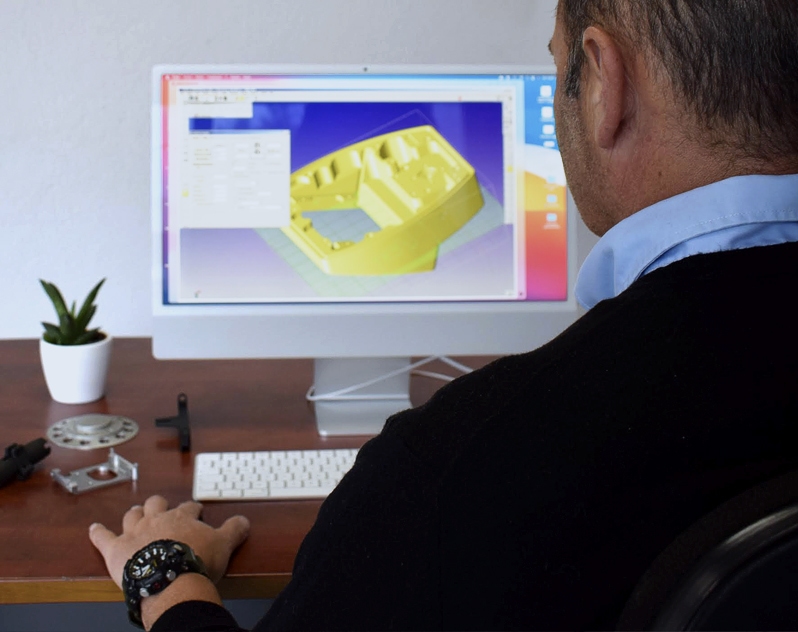

〉 Engineering

Our engineering department specialises in the development of machinery and mechanical accessories for a range of sectors, always based on an idea and striving to meet our goal.

If you wish to work with a professional company specialised in precision machining, do not hesitate to contact us. We can offer advice and create all kinds of parts thanks to our top-quality machinery and advanced technology. Our professional team is highly qualified and capable to handle it and optimise each of the resources that we have in our company.

〉 Machining

We at TECNOVAL have developed a machining process using numerical control, whereby the parts are programmed using CAD/CAM software to deal with 3D geometries.

We actively collaborate with our customers during the development and industrialisation of their projects, working with the most updated software to manage assisted programming. We have a wide range of machinery for machining in 3 and 4 axes and we machine all types of materials, such as steel, stainless steel, aluminium, titanium, brass, bronze and plastics. We also offer technical advice for any customers who require it.

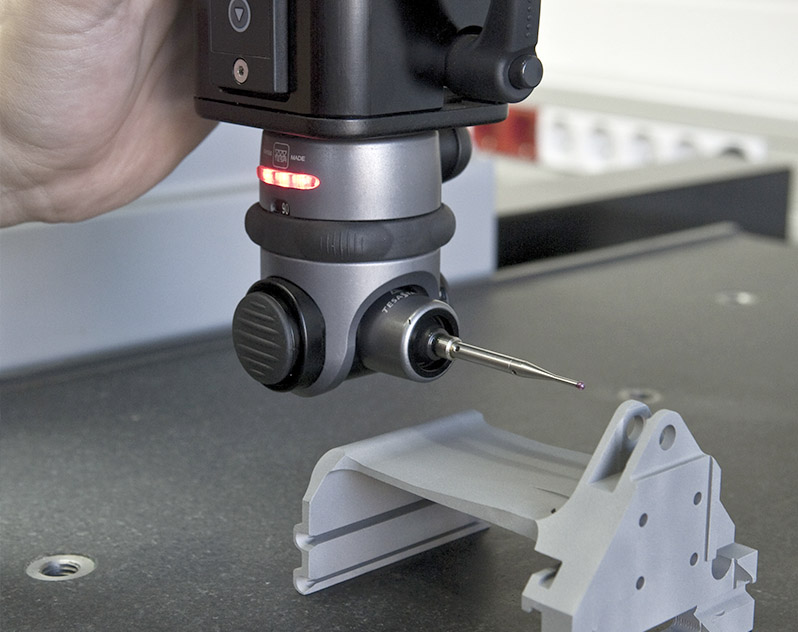

〉 Quality control

Our main goal is to offer the highest quality. This is defined in the precision of the finish of our products, in our seriousness and our meeting of delivery times and utmost collaboration with our customers.

We at Tecnoval have highly qualified staff and a clean room equipped with three-dimensional machinery, vision machinery, surface profile gauges, micrometres, etc. where our products are verified according to the quality protocol agreed with our customers, ensuring that they fully meet the requested requirements.

〉 Treatment

Our goal is to offer our customers solutions in precision machining in order to provide comprehensive management, managing parts with the finish requested by the customer. When it comes to parts’ finishing, we work with a wide range of treatments, such as painting, chemical nickel-plating, anodizing, Teflon-coating, chrome plating, zinc plating and bluing. Contact us for any queries, suggestions or doubts you may have.

〉 Manufacture and assembly

Tecnoval Mechanical Components’ facilities span more than 1800 m² equipped with 2 crane bridges with a capacity of 5 tons to develop our industrial activity with specific assembly areas, different machines and sub-assemblies.

〉 Mechanical welding

We at Tecnoval have different welding technologies to provide any services your company may need. We offer a comprehensive service to allow you to have your welded sets without the need to go through different suppliers. Our machinery is capable of welding with TIG, MIG/MAG and electrode.

ANY QUESTIONS?

Please contact us if you have any questions or concerns. If you do not wish to use our form, send us an email to comercial@tecnovalcnc.com and we will respond as soon as possible.

Garbí, 7, Pol. Ind. Pont del Princep

17469 Vilamalla (Girona) - Spain

〉 Legal notice

〉 Contact

Garbí, 7, Pol. Ind. Pont del Princep

17469 Vilamalla (Girona) - Spain

Engineering

Machining

Quality control

Treatment

Manufacture and assembly

Mechanical welding

〉 Legal notice